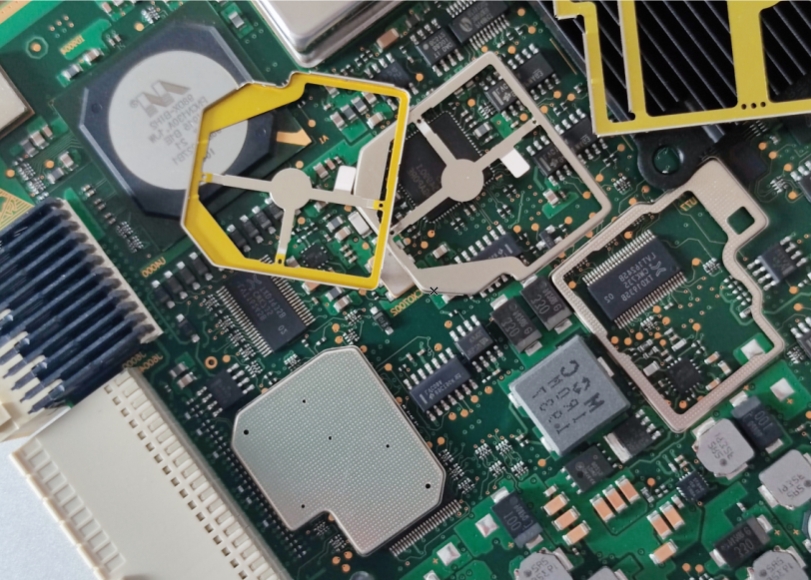

Shield Cover

APPLICATION

- All board level components requiring shielding protection

- Reliable cover design that can withstand vibration and impact

FEATURES & BENEFITS

- T&R packaging to meet automated assembly requirement.

- Strip or roll packaging to fit automatic adhesive assembly.

- Customizable according to design requirements.

- Automatic strip-printing insulating paint process

- Rapid prototyping.

SHIELDING COVER SELECTION CONSIDERATION

Plating Selection - SMT Requirements

- Pre-tinning material - low cost

- Barrel plating - lower cost

- Rack plating - high cost

- Material Selection

Cu-Ni-Zn Alloy

- Tinplate

- Pre-coated Stainless Steel

- Stainless Steel (Cover only)

- Insulation Paint

Structural Design Consideration

- Snap-onassembly

- Strength

- Heat dissipation

- Shielding effectiveness

- Assembly clearance

- Soldering area

- Though-hole mount

Packaging - Automation Requirements

- Tape & Real packaging: automated (suitable for mass production)

- PVC tray: suitable for small order and with requirements for keep leveling

- PE bag: suitable for small order Reflow Soldering Test Requirements

- Peak temperature: 255 ℃

- Test time: 2-5 minutes

Tool Process Consideration

- Drawn process: no gaps around the four corners, higher shielding performance.

- Multi-step drawn process: fit different structural designs.

- Removable shielding cover: fit different structural designs.

EMI shielding is the isolation between two spatial areas to control the radiation of electric fields, magnetic fields, and electromagnetic waves. Specifically, shielding products are used to surround the interference sources of components, circuits, assemblies, cables, or the entire system to prevent the spread of interference electromagnetic fields. Such products may also be used to surround the receiving circuit, equipment, or system to prevent them from being affected by external interference signals. Because shielding components can absorb (eddy current loss), reflect (reflection of electromagnetic waves at the interface of the shielding body), and counteract energy (electromagnetic induction generates reverse electromagnetic fields on the shielding layer, which can partially counteract interference electromagnetic waves) from external interference electromagnetic waves and internal electromagnetic waves on wires, cables, components, circuits, or systems, shielding components have the effect of reducing interference.

(1) When the frequency of electromagnetic interference is high, eddy currents generated in low resistivity metal materials are utilized to form a counteracting effect on external electromagnetic waves, thereby achieving shielding effect.

(2) When the frequency of electromagnetic interference is low, materials with high magnetic permeability should be used to limit the magnetic field lines inside the shielding body and prevent them from spreading to the space that needs to be shielded.

(3) In certain situations, if good shielding effect is required for both high-frequency and low-frequency electromagnetic fields, different metal materials are often used to form a multi-layer shielding body.

SHIELDING COVER + ABSORBER PAD

GoodBon's shielding cover+absorber series combines advanced metal shielding cover and absorber. This unique design shows excellent shielding performance. This series products use SW series absorbing material filling the space between the shielding cover and electronic components. SW series is a silicone rubber absorber independently developed by GoodBon. It is a lightweight and thin magnetic filling material specially designed for the high reflection attenuation of high incidence angle surface waves, suitable for the 2~40GHz frequency band. This composite material is made by adding oil resistant and fire retardant additives, and its elastic base material is high-temperature resistant silicone. The special magnetic filling particles enable the absorber to have excellent attenuation performance when the incident angle is greater than 65 degree. The reflective attenuation testing standard refers to GJB2038A-2011. The absorber is a lightweight, soft, and non-conductive silicone rubber, with an electromagnetic wave absorption attenuation over 10dB at the 40GHz. GoodBon can design and customize according to customer requirements.

SHIELDING COVER + THERMALLY CONDUCTIVE PAD

GoodBon's shielding cover+thermal pad series combines metal shielding cover and ultra-high thermal conductivity in its unique design. A TFP8025 ultra-high thermal pad is applied between the gap of shielding cover and heat generating component. The high performance thermal pad has good compressibility and conformability which makes it fill-up void on the components and lower the thermal impedance. The thermal pad thickness can be customized according to the design.