FleXEAL NF Non-conductive FIP

Product Benifit

- Excellent sealing performance

- Super soft and high rebound

- Super strong adhesion of construction surface

- Excellent weather resistance

Product application

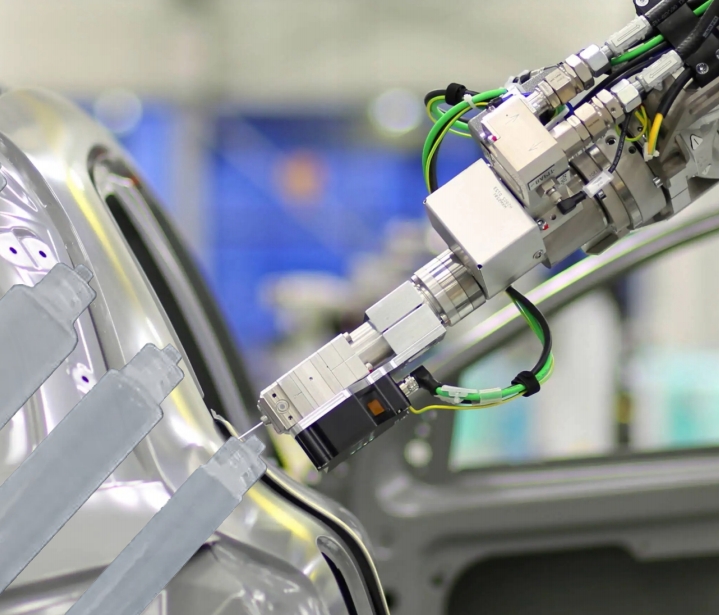

- Communication equipment

- Automotive electronics

- Medical instrument

- IO dust control

- Server

Dispense size

Minimum size: width 0.6 × height 0.4 (mm)

Recommended size: width 1.0 × height 0.73 (mm)

Maximum size: width 2.5 × height 1.7 (mm)

Remarks:

1. The default shape of the dispensing is D type, and the △ type is determined according to the actual product.

2. When the dispensing size exceeds the maximum limit, it is recommended to use rubber strip products.

GoodBon Technology’s eSEAL NF non-conductive FIP series has excellent resilience and environmental sealing performance. It can be dispensed manually or by automatic dispenser. eSEAL NF has the characteristics of low hardness, good elasticity and low compression set, and has good adhesion on various metal and plastic surfaces. The main applications of the product include: wireless communication base station equipment, Automotive, as well as consumer electronics and other fields.

| Parameter | Test Method | Unit | NF1010-10 | NF1011-10 | NF1012-10 | NF1013-10 | NF1014-10 |

| Characteristic | - | - | Universal Type | High and Low temperature resistance |

Rapid Curing | Easy to Flow | Small Size |

| Appearance | Visual Inspection | - | Black/White | Black/Grey | Black/White | Black/White/Grey | White |

| Density | ASTMD792 | g/cm³ | 1.45±0.2 | 1.38±0.2 | 1.43±0.2 | 1.25±0.2 | 1.2±0.2 |

| Hardness | ASTMD2240 | ShoreA | 40±5 | 45±5 | 40±5 | 20±5 | 25±5 |

| Viscosity (23 °C) | - | Pa*s | 100±15 | 一 | 100±15 | 20±5 | 60±10 |

| Compression Set | ASTM D395-B | % | 30 | 30 | 30 | 30 | 30 |

| Tensile Strength | ASTMD412 | MPa | 2.2 | 2.0 | 2.1 | 0.7 | 2.0 |

| Elongation at Break | ASTMD412 | % | 150 | 380 | 350 | 150 | 150 |

| Volume Resistivity | GB/T1692-2008 | Q.cm | 1.0x10¹⁴ | 1.0x10¹⁴ | 1.0x10¹⁴ | 1.0x10¹⁴ | 1.0x10¹⁴ |

| Breakdown Strength | GB/T1695-2005 | Kv/mm | 18 | 18 | 18 | 18 | 18 |

| Shear Strength | GB/T11211-2009 | MPa | 2.2 (Al) | 2.0 | 2.2 | 1.5 | 2.0 |

| Surface Dry Time | GB/T13477.5-2002 | min | 10 | 4 | 8 | 10 | 10 |

| Complete Curing Time | GB/T13477.5-2002 | HI | 24 | 4 | 12 | 24 | 24 |

| Flame Retardant Grade | UL94 | - | HB | HB | HB | HB | HB |

| Temperature Resistance Range | - | ℃ | -50~+170 | -60~+260 | -60~+200 | -50~+170 | -50~+170 |

| Storage Temperature | - | ℃ | -20~+30 | -20~+30 | -20~+30 | -20~+30 | -30~-10 |

| Storage Time | - | month | 6 | 4 | 6 | 6 | 3 |

| Parameter | Test Method | Unit | NF1015-10 | NF1016-UV | NF1017-20 | NF1018-10 | NF1019-10 |

| Characteristic | - | - | Low Volatility | UV Curing | High Temperature Curing | Thermal Conductivity 1.2w | Strong Adhesion |

| Appearance | Visual Inspection | - | Black/White/Grey | Translucent semi flowing | Semi Bright/Black/Grey | White/Black | White |

| Density | ASTMD792 | g/cm³ | 1.45 | 1.2 | 1.2 | 1.93 | 1.2 |

| Hardness | ASTMD2240 | ShoreA | 38±5 | 15±5 | 35±5 | 70±5 | 35±5 |

| Viscosity (23 °C) | - | Pa*s | 100±15 | 40±10 | 40±10 | 一 | |

| Compression Set | ASTM D395-B | % | 30 | 30 | 30 | 30 | 30 |

| Tensile Strength | ASTMD412 | MPa | 2.2 | 2.0 | 3.0 | 2.0 | 4.0 |

| Elongation at Break | ASTMD412 | % | 350 | 300 | 300 | 35 | 150 |

| Volume Resistivity | GB/T1692-2008 | Q.cm | 1.0x10¹⁴ | 1.0x10¹⁴ | 1.0x10¹⁴ | 1.0x10¹⁴ | 1.0x10¹² |

| Breakdown Strength | GB/T1695-2005 | Kv/mm | 18 | 18 | 18 | 12 | 12 |

| Shear Strength | GB/T11211-2009 | MPa | 2.0 | 2.0 | 2.5 | 1.5 | 3.5 |

| Surface Dry Time | GB/T13477.5-2002 | min | 12 | 一 | 10 | 5 | |

| Complete Curing Time | GB/T13477.5-2002 | HI | 24 | 0.05 | 150℃/30min | 24 | 8 |

| Flame Retardant Grade | UL94 | - | HB | HB | HB | V0 | HB |

| Temperature Resistance Range | - | ℃ | -60~+120 | -50~+120 | -60~+200 | -60~+200 | -50~+120 |

| Storage Temperature | - | ℃ | -20~+30 | +8~+25 | -20~+5 | -20~+30 | -20~+30 |

| Storage Time | - | month | 6 | 6 | 6 | 6 | 3 |