FleXEAL EF Conductive FIP Gasket

Product Benifit

- Friction resistance, high temperature resistance, can be

disassembled repeatedly - Excellent electromagnetic shielding effect to achieve

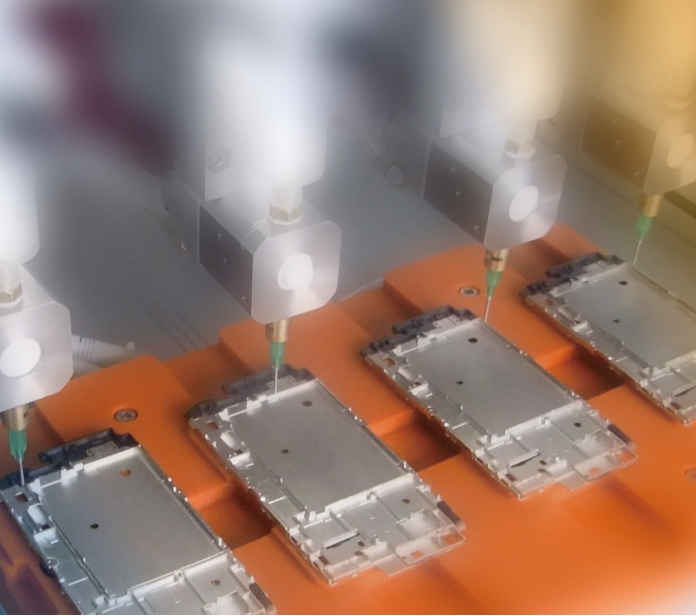

electromagnetic compatibility - Automatic dispensing saves labor and assembly time

- Support fast proofing, low tooling cost

Product application

- Communication equipment

- Automotive electronics

- Medical instrument

- IO dust control

- Server

GoodBon Technology’s eSEAL EF product series includes different conductive particle formulations, high shielding effectiveness, room temperature or high temperature vulcanization and other product options. The fluidity of the glue is good, which is convenient for dispensing and construction; after curing and molding, it has excellent adhesion, and has good wear resistance and can withstand repeated disassembly and assembly, low compression permanent deformation and other characteristics. The adhesive can be reliably bonded to various metal and plastic surfaces, making the product suitable for optical communication modules, 5G communication base stations, radar equipment, automotive electronics, consumer electronics, etc.

Dispensing Structure Design Suggestion and Performance Test Method

GoodBon Technology is dedicated to the enterprise mission of "One-stop Solution for Material Science and Smart Manufacturing Service", and continuously improves and innovates the product series to help our customers reduce operating costs and improve production efficiency. Customers can comprehensively solve dispensing, potting and other automation control solutions.

Suggestion for Size Design of Dispensing Structure

The professional technical support team of GoodBon Technology actively helps product designers to choose the appropriate dispensing path and dispensing section; after the glue is vulcanized and formed, different sections correspond to different aspect ratios.

- D section: aspect ratio 0.75:1, suitable for most dispensing product

- △section: aspect ratio 1:1, suitable for limited width but products with certain height requirements

- Double D-shaped section: aspect ratio ≥ 1:1, suitable for height requirements products with larger than width

Product performance testing methods provided by GoodBon’s physical laboratory, chemical laboratory, reliability laboratory, and electromagnetic compatibility laboratory can help with most material tests. Experienced quality inspectors strictly inspect the products before each batch of products is shipped to ensure that the size is qualified and the performance is stable.

Adhesion test: According to Goodbon new material internal standard QA-WI-FIP-002, refer to HW DKBA04800202_FIP technical requirements

Volume resistivity test: According to MIL-DTL-83528C standard

High and low temperature test: According to MIL-DTL-83528C standard

Shielding effectiveness test: According to MIL-DTL-83528C standard

| Parameter | Test Method | Unit | EF2111-20 | EF2120-20 | EF2121-10 | EF2125-10 | EF2310-10 | |

| Characteristic | - | - | Super Soft | High Flow Rate | Super Soft | Superfine | Corrosion resistance | |

| Conductive Material | - | - | Ni/C | Ni/C | Ni/C | Ni/C | Ag/Al | |

| Base Material | - | - | Silicon Rubber | Silicon Rubber | Silicon Rubber | Silicon Rubber | Silicon Rubber | |

| Curing Conditions | - | - | High Temperature Curing | Normal Temperature Curing | ||||

| Curing Temperature | - | ℃ | 150 | 150 | 25 | 25 | 25 | |

| Curing Time | - | - | 30min | 30min | 24Hour | 24Hour | 12Hour | |

| Hardness | ASTMD2240 | ShoreA | 45 | 60 | 45 | 45 | 60 | |

| Tensile Strength | ASTMD412 | PSI | 150 | 150 | 150 | 120 | 130 | |

| Ductility | ASTMD412 | /U | 100 | 100 | 100 | 100 | 180 | |

| Density | ASTMD792 | g/cm³ | 1.9 | 1.9 | 1.9 | 2.2 | 2.2 | |

| Volume resistivity | MIL-DTL-83528C | ohm-cm | 0.04 | 0.03 | 0.04 | 0.04 | 0.008 | |

| Compression Ratio 70 hours at 100 °C | ASTMD395-B | % | 30 | 30 | 30 | 30 | 30 | |

| Working Temperature | - | ℃ | -55~+125 | -55~+125 | -55~+125 | -55~+125 | -55~+125 | |

| Flame Retardant Grade | UL94 | - | V-0 | V-0 | V-0 | V-0 | V-0 | |

| Shielding Efficiency (AVG 200MHz~18GHz) |

MIL-DTL-83528C | dB | >90 | >90 | >90 | >90 | >100 | |

| Adhesion Dispensing Size w1.1xh0.9xl10mm |

QA-WI-054 | N/cm | >10 | >10 | >10 | >10 | >10 | |

| Dispensing Size w1.1xh0.9xl10mm @30% compression of rebound force |

QA-WI-058 | N/cm | 20 | 43 | 21 | 14 | 35 | |

| Dispensing Size Minimum/Maximum Recommended Value |

Width x Height | mm | 0.7*0.5/ 2.5*1.7 |

0.7*0.5 2.5*1.7 |

0.5*0.35/ 2.5*1.7 |

0.35*0.35/ 2.5*1.7 |

0.6*0.4/ 2.5*1.7 |

|

| Effective Storage Time | - | Month | 6 | 6 | 3 | 3 | 3 | |

| Storage Conditions | - | ℃ | -30~-10 | -30~-10 | -30~-10 | -30~-10 | -30~-10 | |

| Parameter | Test Method | Unit | EF2510-10 | EF2511-10 | EF2610-10 | EF2611-10 | EF2610-20 | EF2610S-20 |

| Characteristic | - | - | High Performance | Quick Surface Drying | High Resilience | Small Size | Low Temperature Fast Curing | |

| Conductive Material | - | - | Ag/Cu | Ag/Cu | Ag/Ni | Ag/Ni | Ag/Ni | Ag/Ni |

| Base Material | - | - | Silicon Rubber | Silicon Rubber | Silicon Rubber | Silicon Rubber | Silicon Rubber | Silicon Rubber |

| Curing Conditions | - | - | Normal Temperature Curing | High Temperature Curing | ||||

| Curing Temperature | - | ℃ | 25 | 25 | 25 | 25 | 120 | 120 |

| Curing Time | - | - | 24Hour | 12Hour | 24Hour | 24Hour | 2Hour | 2Hour |

| Hardness | ASTMD2240 | ShoreA | 60 | 55 | 50 | 50 | 55 | 50 |

| Tensile Strength | ASTMD412 | PSI | 130 | 130 | 200 | 200 | 150 | 150 |

| Ductility | ASTMD412 | /U | 150 | 150 | 100 | 180 | 100 | 100 |

| Density | ASTMD792 | g/cm³ | 3.2 | 3.0 | 3.8 | 3.8 | 3.9 | 3.9 |

| Volume resistivity | MIL-DTL-83528C | ohm-cm | 0.003 | 0.004 | 0.005 | 0.01 | 0.01 | 0.01 |

| Compression Ratio 70 hours at 100 °C | ASTMD395-B | % | 30 | 30 | 30 | 30 | 30 | 30 |

| Working Temperature | - | ℃ | -55~+125 | -55~+125 | -55~+125 | -55~+125 | -55~+125 | -55~+125 |

| Flame Retardant Grade | UL94 | - | V-0 | V-0 | V-0 | V-0 | V-0 | V-0 |

| Shielding Efficiency (AVG 200MHz~18GHz) |

MIL-DTL-83528C | dB | >110 | >100 | >100 | >100 | >100 | >100 |

| Adhesion Dispensing Size w1.1xh0.9xl10mm |

QA-WI-054 | N/cm | >10 | >10 | >10 | >10 | >10 | >10 |

| Dispensing Size w1.1xh0.9xl10mm @30% compression of rebound force |

QA-WI-058 | N/cm | 39 | 40 | 25 | 19 | 28 | 28 |

| Dispensing Size Minimum/Maximum Recommended Value |

Width x Height | mm | 0.5*0.35/ 2.5*1.7 |

0.5*0.35/ 2.5*1.7 |

0.5*0.35 2.5*1.7 |

0.3*0.3/ 2.5*1.7 |

0.5*0.35 2.5*1.7 |

0.5*0.35/ 2.5*1.7 |

| Effective Storage Time | - | Month | 3 | 3 | 3 | 3 | 6 | 6 |

| Storage Conditions | - | ℃ | -30~-10 | -30~-10 | -30~-10 | -30~-10 | -30~-10 | -30~-10 |